There is a lot of refinement and cleanup to do, but the solar water pump is up and running! Sort of.

Half of the project is usually hooking everything up and half is cleaning up and making pretty. The solar water pump is pumping, but there is a lot yet to do. My final rib (dog, motorcycle, old man, sad story in Part 2) seems to have knitted into place, so I can no longer use mortal agony as an excuse to get out of work.

I started off talking about different ways to store your solar energy. There are lots of ways that are cheaper than batteries. In this project, we are doing a small pumped storage demonstration. These days, pumped storage on a large scale means pumping to a mountaintop lake when there is excess sun or wind energy and letting it flow back through a turbine to make electricity when it is dark. My project doesn’t make electricity at night, but it avoids using electricity to bring water under pressure into the house at night. The old water-powered ram pump or the new solar pump pushes the water through 3000 feet of pipe, up a hill to the 600 gallon tank on the top of the hill. The elevation difference keeps the house tank pressurized, instead of using an intermittent pump.

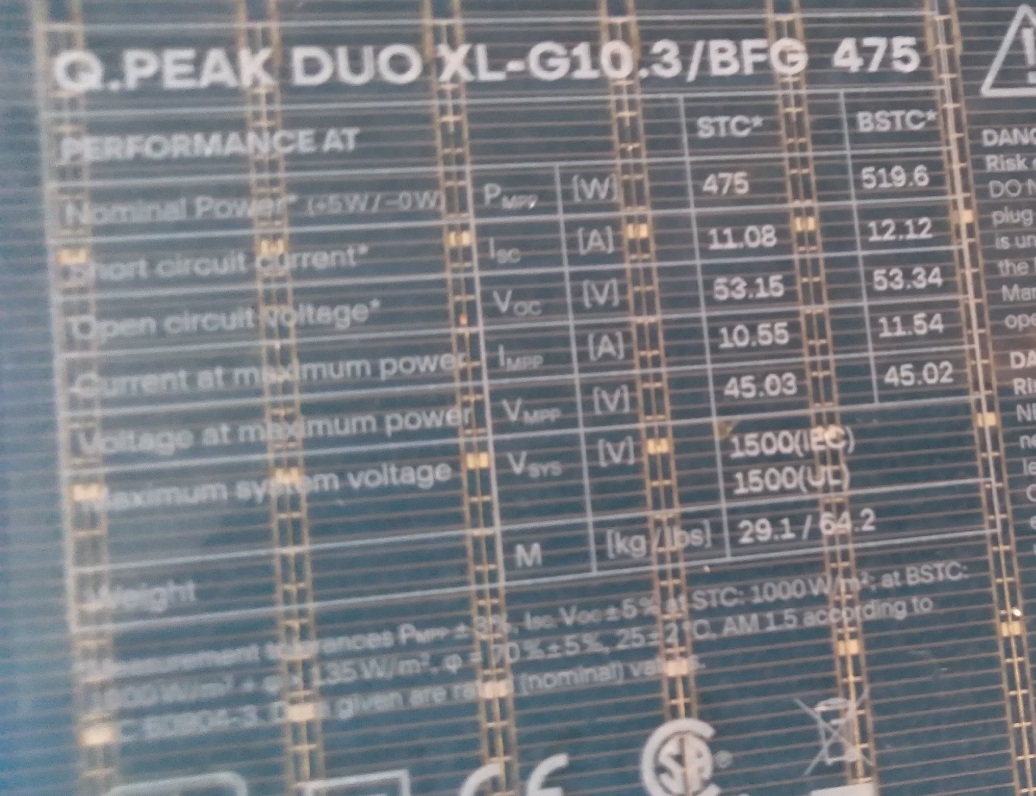

I guesstimated (see Part 2) that the big, cheap spool of surplus 10 gage wire would be adequate to run the pump and that a single 475 bi-facial PV (photovoltaic) panel would be adequate to push the electrons through the long wire needed to put the panel in an open space. I guesstimate correctly , at least as pertains to a bright, sunny day. Further testing will ensue, after some refinements are added.

Oh, and about that panel, I bought a stack of them when Sun Electronics had them on sale. I needed some for my yacht project, but found them to be bulky and heavy for most other purposes. I had extras in stock, so that is why I chose this one to power the pump. I still had one loose rib when I wrestled this one onto the bed of my truck to haul it down the hill, so it was a bit of a chore. John has LOTS of smaller panels you might consider for your projects. They are much easier to handle and cost about 1/4 what the big ones do for a given amount of power. Just sayin’.

My helper, Luscious, was not available to help on wire pull day…it is deer hunting season. I still had 2 ribs rattling loose, but this was not a terribly difficult job. I laid a shovel across the back rails of the work buggy to serve as an axle for the spool of wire, pointed it in the right direction and started off through the jungle with end of wire in hand. You’d be surprised how stiff the pull can be after a couple of hundred feet, but 10 gage wire is pretty robust. I am not burying the wire. It will pretty much self-bury in the swamp. Suspending it above ground would be a bad idea, due to falling tress.

I had on my snake chaps, but in all of this, I have not seen a single moccasin. Amazing. Maybe they thought Luscious was with me. She packs heat and they know it.

The standpipe that collects water from the spring and feeds it to the ram pump was to be used to emulate a well. It was 2″ in diameter. So is the pump, so that was not going to work. I sawed off the 2 inch pipe and used a reducer to put a 4″ pipe atop the 2″ pipe stub. Problem solved. That’s in the photo below.

The control box was mounted on a painted slab of exterior plywood and screwed to a tree. Yes, a 4×4 post might have been preferable and I may yet move it to one. The control box has a MPPT (maximum power point tracker) controller to drop the panel voltage (and increase the current), a battery control circuit (unused in our application, but available for 24 hour service), brushless pump motor controller (actually a 3 phase ac motor) and various sensing and safety circuits. No inverter, no charge controller, no battery, big bucks saved.

An adapter fitting was screwed into the pump, a 400 psi-rated hose was attached to that and a haul-out line was tied to the pull rings. Hopefully the pump will not require frequent visits, because the ladder I have down there is not the best. I fed pump, rope, power cable. output hose and water level sensor down the pipe and tied it off at the selected level. Now to connect.

The solar panel was connected first. I had to scramble to find some MP4 connectors. Usually, I maintain a good supply of them, but I am about out. There could be a sack full of them buried on my work bench, too. Down at the other end, I carefully stripped the wires and checked for polarity. This may not be the safest way of doing things, because while 50 volts is not likely to kill you it can give a tingle. With polarity determined, I connect the wires to the power input terminals.

The pump motor cable was extended and the wiring colors were different, so I had made notes as to the proper connection of the 3 wires to the motor. The cable was a little long and I will probably trim it a bit for less resistance once the prettifying is done. It will probably help starting torque.

–Time Out!– The motor here is what is advertised as “brushless DC” or BLDC. Usually that is the way it seems because the control circuitry is buried inside, out of sight. Apply the appropriate DC power and the starts to work. Fans in your PC, a lot of power tools and electric car motors tend to be BLDC, these days. Motors work by flipping and flopping electromagnetic fields and a purely DC motor requires brushes to do this. BLDC motors tend to be 3 phase AC motors with a sort of inverter or DC to AC conversion circuit that makes 3 phase power. It does not have to be high voltage. In this case, the AC power is only about 24 volts. The frequency of the current can be changed to allow the motor to run faster or slower. That’s a handy feature when trying to get a motor up to speed with a limited power source. I think they are probably cheaper to build, too. — Back to our regular program.—

The water level sensor was connected. It is on top of the pump and shuts the system down if the water level in the “well” drops too low. The manufacturer assures the user that running the pump dry will cause its immediate demise. Curiously, the controller came with that connection jumpered.

Two other connections allow for sensing if the water tank is full. Ummmm…I’m not running a 3000 foot wire. It can just overflow.

Moment of truth time. There was a red LED on the circuit board inside as soon as I connected the solar panel. Nothing outside. I flipped the power switch and got 3 green lights on the front panel. Green is usually good, and after a few seconds I heard the motor start. The pump is variable speed and the control box slow-starts it. That’s a good thing. Lots of water began to flow from the unconnected hose. Success!

Now for the real test: operation under pressure. Water and electricity are often compared in operation. The long wire from the solar panel, normally considered pretty big, is acting as a resistance because of the length. Likewise, the 3000 foot pipe to the tank, 1.25 inches in diameter, is pretty big, but is a real resistance owing to the length. Other resistances involved come in the form of various valves and fittings. A standard hose bibb valve may be 3/4 inch, but the hole inside is only about 3/8. All this stuff adds up. Will it flow? Because of hydraulic weirdness that departs from the electrical analogy, will the pump even start, considering it is pretty near the maximum rated pressure just sitting there?

Okay, I know a little about hydraulics and anticipate that it will have trouble starting. This can be dealt with in a couple of traditional ways. My old ram pump, as well as the old piston-type electric pumps, uses an air chamber to buffer the pulses from the pump. Once underway, the solar pump will not have much in the way of pulses, but the start is going to make one. The pulse shockwaves travel at the speed of sound in water, which is lots faster than the speed of sound in air, and can cause all manner of havoc. Controlling the havoc of shock waves is exactly how the ram pump works. Anyway, a small expansion chamber may be all I need. City folks seem to have a small expansion tank atop their water heaters. We country folks don’t, but I have one from a roof cooler project.

I have another trick up my sleeve: an unloader valve. Most air compressors have a valve that lets the motor get the pistons pumping without starting against the air pressure in the tank. I need something like that, but in the Grainger catalog I find some industrial valves that are OMG priced. Being a clever fellow, I can make one from common components for under $20, even incorporating the air chamber I found in the junk pile.

Cutting to the chase, I connected the pump to the main water line and gave it a try. The pump made a whimpering noise and the fault light came on at the control box. Nice: fault protection. Okay, I figured as much, but will it pump if I can give it a break on starting? I loosened the line enough to relieve pressure and the pump started. When I tightened the fittings it continued to run. By the time I made it up the hill to the tank, there was already a noticeable increase in the water level. I went to the house for lunch and by the time I returned to the hill, the tank was overflowing.

A quick mental guestimation of the overfilling of the tank tells me the pump is running at spec, despite the aforementioned resistances. In fact, because of those resistances and the house being halfway up the hill, the house tanks were boosted to 37 psi. That will not only give a bit of knockdown power at the shower head, but I can foresee running multiple sprinklers in an attempt to restore my lawn next summer. For some reason, UPS, USPS, FEDEX and Amazon drivers have conspired to establish a circular drive on my lawn. With water, fertilizer and my own mini Maginot Line I can have a lawn, again.

So, I have a couple of parts on order to establish my unloader. I will probably test the chamber and the unloader separately, but am prepared to combine them. Assuming this gets the pump running from a standing start, the next tests will involve cloudiness and variable levels of sunlight. I still have solar panel options and in the cleanup, the motor power cord can be shortened a bit to improve the current. I anticipate success. I think my plans for use have changed, though. With that much water pumping, rather than just leaving it on all the time, I may just run it once or twice a week when the tank needs topping or during sprinkling season.

There is a chance I can come up with some sort of a pressure sensor to anticipate a full tank, but because of the pipe flow resistance there can be no accurate measurement when the pump is running. Something to think about.

As far as cleanup goes, I will probably include the removal of some large chunks of concrete and various bits of pipe from past projects. I should have an update, soon. __Neal