You Can Do This, Too

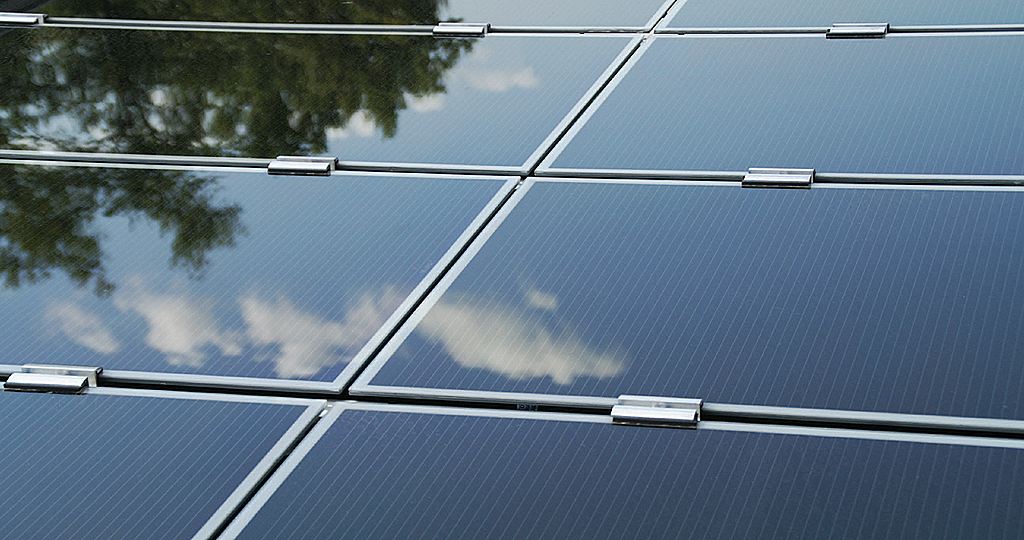

Lunch for two today at Arby’s cost 35 bucks. Can you believe that??? For that you can get 350 watts of solar panels from Sun Electronics. Just switch to raman noodles. In a month’s equivalent you could have panels equal to the typical installation those pesky solar installers put up. That’s enough to cover a […]

You Can Do This, Too Read More »