There’s the power you think your solar power system should put out and then there is the actual amount and they are not the same. You can usually do something about that. What’d you think I meant?

My new 10 panel, 2500 watt, solar array is just about finished. I need a few clamps and I’m going to add a quick disconnect, but it is running and stable. It isn’t putting out 2500 watts though. We’ll go over some things to look for if your system is not performing at expected levels.

First off, understand that your modules are rated at a certain temperature, with the panels dead-on into the sun and the sunshine full and bright. There aren’t many places where you can meet those conditions unless you have a tracking mount. So, just get it in your head that it isn’t going to be 100%. Let’s get close as we can, though.

Let’s start at the panels. If they are adjustable or trackable, are they aimed right? Trackers use power and require maintenance. You can buy more panels and pretty much make up the difference without trackers.

Here’s an obvious one: are the panels clean? I took a rag to one of my panels and just scrubbing about a square foot turned it black! It didn’t LOOK dirty, but it sure was! This afternoon I got the windshield scrubber out and went down the row. Oh, my goodness the black water was just rolling off. I had cleaned them after pine pollen season, but not since crop duster season. A 1200 hp engine can kick up a lot of dirt when trying to launch 16,000 pounds of airplane, but it just didn’t show. I just need some full sunshine to see if there is improvement. You may not have crop dusters, but mines, quarries and coal plants can kick up a lot of particulate matter. Even brake dust from traffic.

Go down the line of panels and check your MC4 (or whatever) connectors. MC4s should be tight and clicked in. If not, you could get a poor fit, high resistance and heat. Many’s the WalMart roof that has been seen taking a smoke break owing to loose-fitting connectors. Check with a thermometer gun or just feel.

Are your wires big enough? Usually the solar wire is AWG10, but I have noticed with the wire shortages that there is a lot of thinner 12 gauge wire on the market. A solar string usually runs around 8-10 amps, so that is not an issue unless you are running parallel strings and pushing the limits of the wire. Heaven help you if you got ahold of some Chinese fake solar wire. More on that in a minute.

I saw on a boat forum where a guy was not getting much power from the new solar system on his boat. He had installed two 100w panels and was getting a little under 100 watts. His 12v system had a PWM charge controller, which did not work well with the 40 volt input he had from the two “12 volt” panels in series. He would have been fine with an MPPT controller. Changing to a parallel configuration saved the day. The question, then, is your system wired correctly?

Are you getting shade? Poly- and monocrystalline panels are really fussy about shade, especially the small panels. Full size panels tend to have 3 complete circuits, so a partial shade may not shut down the entire panel and the entire string. If shading is an issue, you might be better off with less series and more parallel connection, keeping in mind the charge controller’s needs. In other words, you might connect for two 60 volt circuits instead of one 120 volt circuit.

Finally, do you have hot spots? An IR thermometer gun is good for scanning panels, but you can use your hands. Rub your hand across the panel and it should be warm-to-hot if the sun is out. If your fingertips melt crossing a particular cell, you have a problem and that panel should be removed, repaired or replaced. It could have a bad diode in the plastic box on the back. The next step is the cell turns brown. Shortly after that the glass explodes, so this is something best caught early.

I know that a few dozen panels in the roof of my Solar Shed are not connected, as I was planning an expansion. These are small panels, but I can pick up around 800 watts, just by using what are not plugged in. There are lots of strings of these modules that ARE plugged in, but two strings have a problem and I have pulled the fuses. If you have multiple strings that are all the same, and can isolate them, it is real easy just to turn the strings on one at a time and watch the power increments. Understand that these modules of mine have been stomped and thrown off the roofs of earlier installations, so they sometimes have issues that new panels would not. Usually a diode has blown and the bad one in a string of 21 panels can be found…but NOT during the summer. It is 140 degrees up there. I could use that extra 1500 watts, but I can get by without it until January.

Moving on, the next stop will be a disconnect, combiner box and charge controller. You need to periodically snug up the screws to keep the connections good. Any signs of heat should be a call to action. The meters on your charge controller are usually sufficient to show that power is coming and going and the charge controller usually works or it doesn’t. I did recently see a Midnite Solar 250 that appeared to be running, with input, but no power was coming out. That will turn out to be some charred transistors inside. That may be beyond your technical abilities, but take heart in the fact that the mainstream makers, like MS, can repair gear for a whole lot less than the price of a new one.

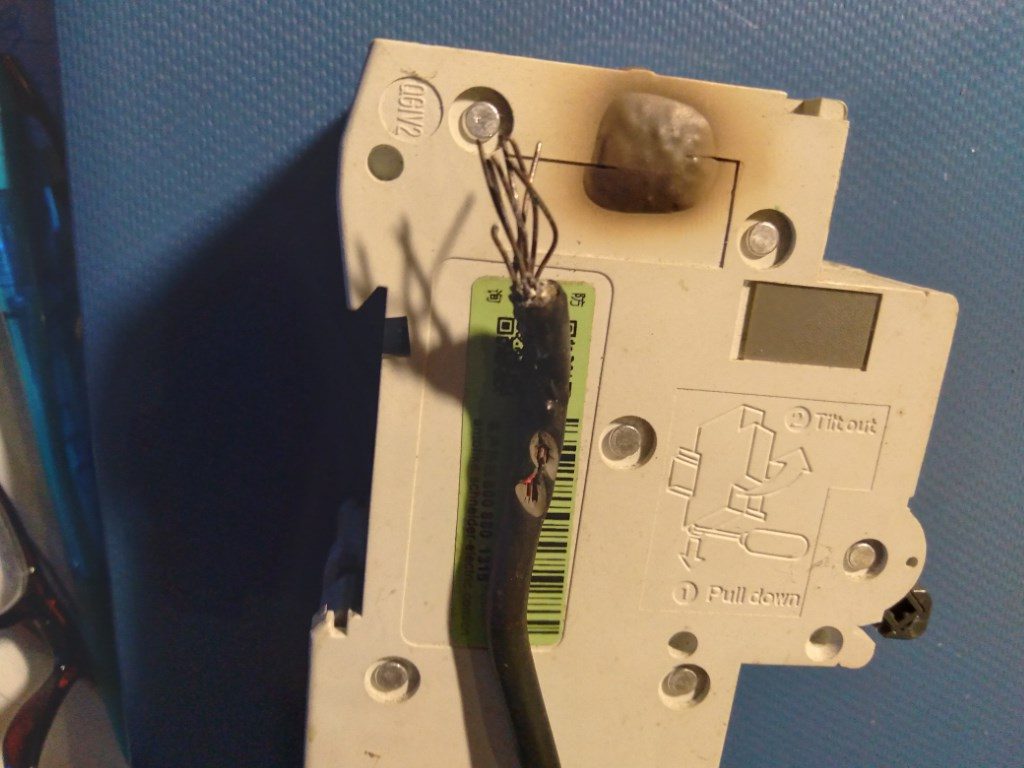

I recently looked in on my Zero Export Grid Tie system and discovered the charge controller to be dark. A closer look revealed that the wire to the output breaker was melted and the breaker was browned. I swapped the breaker, which was actually ok, with a new one from the spares and replaced the wire and all was fine. (Charred components do not impress people who see your system.) Remember I said we’d get back to Chinese fake wire? I got a roll of it some years ago and thought I had discarded it all, but about 4 inches of it remained in my wire drawer, it seems. It isn’t really copper and the aluminum core just disintegrates very quickly. The high resistance browned the breaker and melted the insulation.

Now we’ll make our way to the battery and or inverter. Here you get into some serious amperage and clean, tight connections are a must. If it is too hot to touch, it is too hot. Battery terminals can melt if left too loose and then the battery is ruined. (See my post on repairing battery terminals) Sometimes a battery will develop a shorted cell and a lot of power will be wasted trying to charge it. If a flooded cell battery is really going through a lot of water, then something is wrong. It could be charge settings or it could be time to say goodby to the battery.

If everything seems ok to here, but the battery just does not last, it may be time to equalize and/or desulfate your lead acid batteries. This can rarely be done online with solar power only. If you have multiple banks, you can pull them off one at a time to condition them, while keeping the system running.

Those are just a few suggestions. Other sneaky problems can creep in, but I think I’ve given you a start.–Neal