If you are looking for a scandal, sorry. I’m talking about actual dirt.

Just about any serious piece of electronic gear comes with a manual, which I am certain you read cover to cover 3 times before attempting to install…right? Somewhere in there you will usually find the admonition to “mount in a cool, dry place with temperature range X to Y, and humidity below 95%, non-condensing.” Or something like that. If you just paid 5 grand for a fancy inverter, you probably go along with that.

The 95% humidity thing is always worth a giggle here in La Florida. Sometimes the humidity is actually below 95%, but not for long. Sometimes it is more like 120%. Seriously! Many nights we’ll get a convection fog that just rolls right through the shop end of my Solar Shed, getting my motorcycles and tools sopping wet. That’s where you bust that “non-condensing” bit in the manual.

If there is any dust or dirt on the circuit board and you add some damp while power is applied, the electrons can start making unintended paths and and doing unintended things. This is especially the case where you are making 120 or 240v in the same box where the control circuits are 5 volts. I avoid this with Sun King, my solar-powered launch, by just leaving it on all the time. The little bit of heat from the circuits keeps the moisture out.

My solar power system for the house is actually two in parallel. In the winter I run the inverter in the control room to help keep the Man Cave warm. In the summer, I run the other inverter, which is mounted in a cabinet outdoors. This keeps the Cave cooler with less a/c. Ideally, the summer inverter should be in the a/c, but it is actually designed for high temps. It is not designed for high moisture of winter, so I leave it powered up on standby to keep the humidity out. There is also a Midnite Solar 250 in there that can get pretty warm when the sun comes out.

This gear is treated pretty well and within specs. A little wipe with a clean 2″ paint brush every now and then is sufficient to keep the screens clean to allow good airflow for cooling.

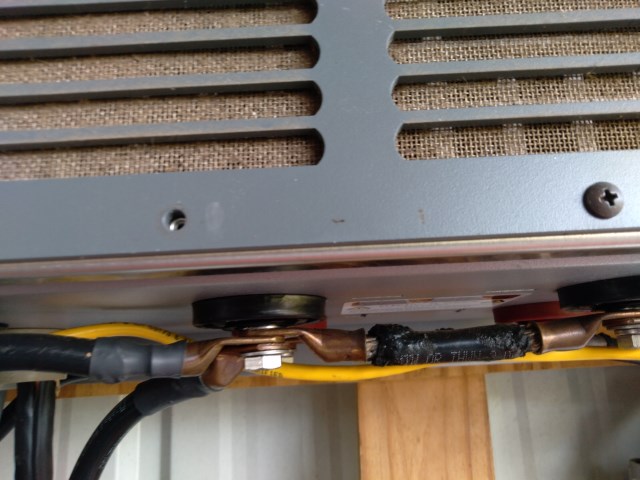

Then there are the buggy inverters. My electric farm vehicles are pretty much never clean and dry. They get used for pretty much every purpose on the farm from hauling firewood, towing trailers or joyriding. The inverter runs the electric chainsaw I use for firewood. I have given up on gas saws. Fortunately, there are some serious electric saws, like my Oregon. The battery saws are ok for light work, but not for prime time. I cut down a couple of trees and buck them to the size the furnace likes, then haul them back to the woodpile. Lots of dirt and bark is involved and there is usually a thick layer of it on the cargo bed and some invariably settles down on top of the inverter.

Should I be surprised that the inverter in the Yamaha started acting funny and quit. No.

Here is step one of my cure for dirty electronics. I put the inverter on the clean workbench so I would not lose parts. Then I removed the cover and went after it with a paintbrush and air hose. Yup, it was cruddy in there, but once it was all cleaned up and put back together again it worked for another few loads of wood. But it was too soon to celebrate. We had more dirt and one of those really soggy fogs roll through. This time, the brush and blow did not do the trick, so time for Plan B. I had the notion that humidity had gotten into the transformers or inductors where it should not be, so I determined to drive it out. The dashboard of your car on a hot day with the windows up can make a fair oven, but so does an actual oven. The wife and my ex-daughter’s sister (long story) were baking a treat one afternoon after school, so when it was done I let the oven cool a little and popped the inverter in until it was completely cooled down.

Sounds crazy, but it worked and I avoided freezing to death with my firewood supply resumed. Freezing? Florida? Yeah, it happens a lot in Northwest Florida. If you try the oven trick, just preheat to a temp that won’t melt plastic and turn the oven off. It is a desperate measure, but with sound underlying principle. Besides, the thing wasn’t working, anyway, so what’s it going to hurt?

–Neal