Us Vs. Them

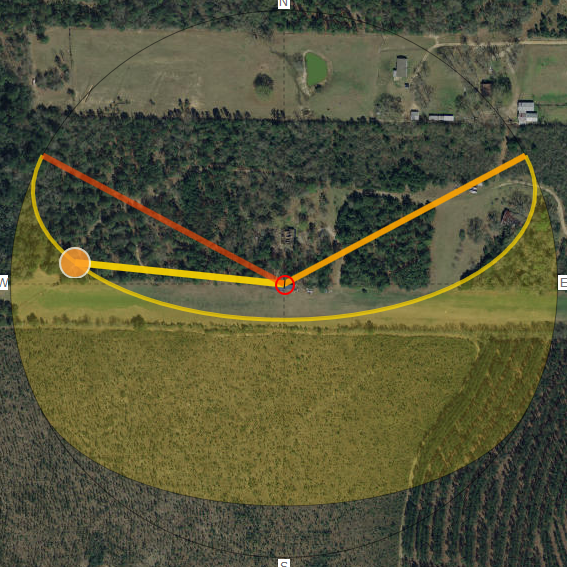

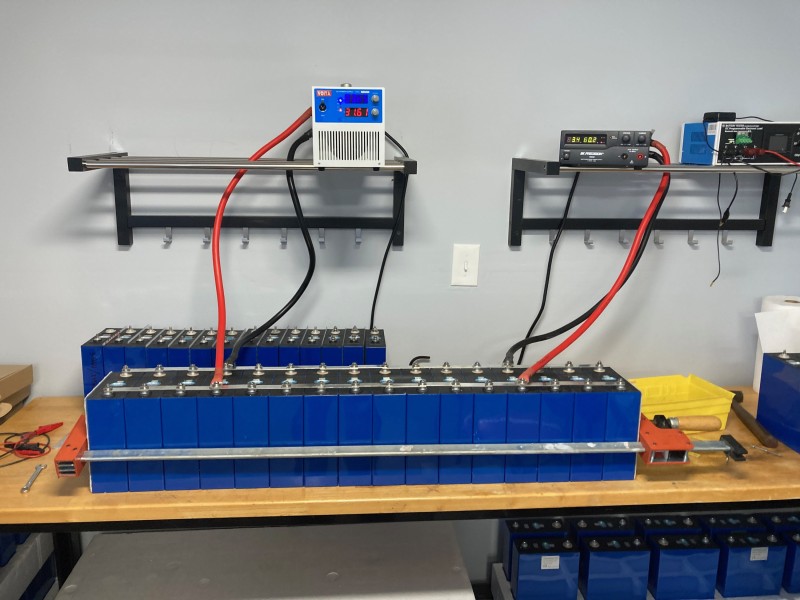

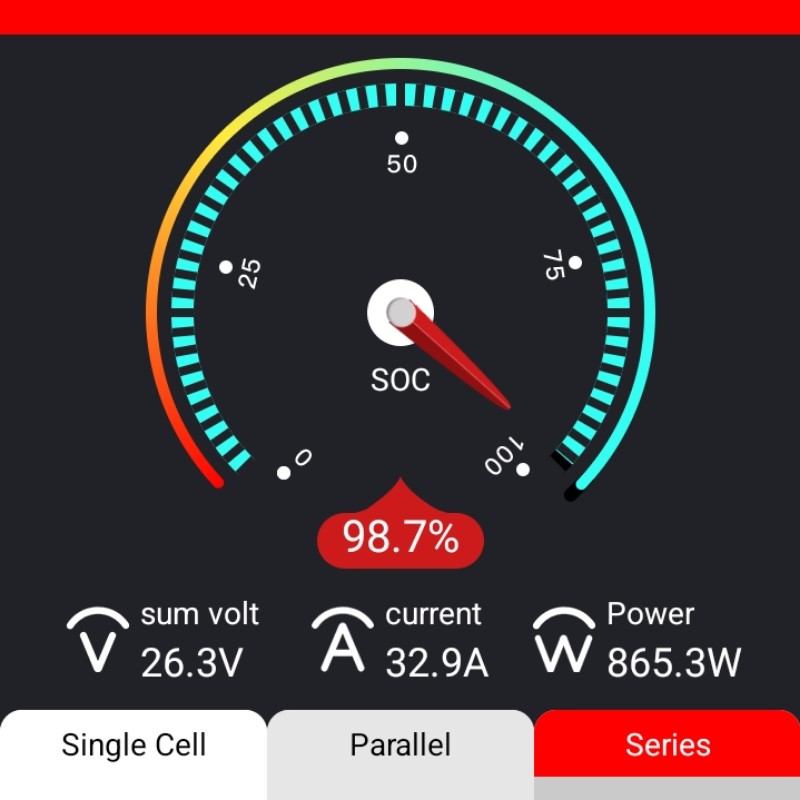

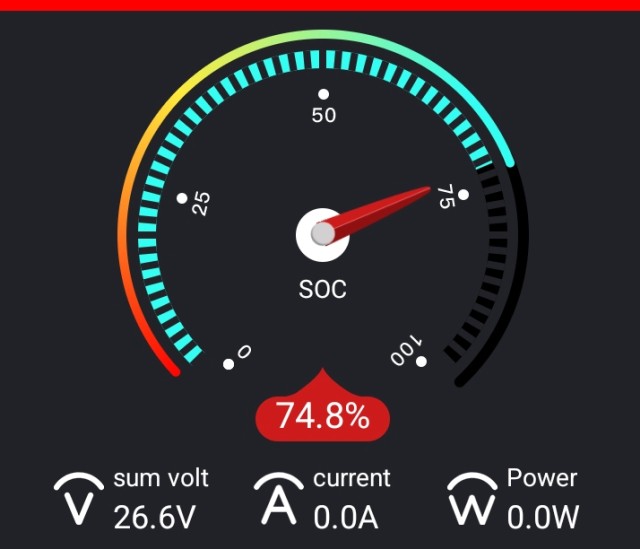

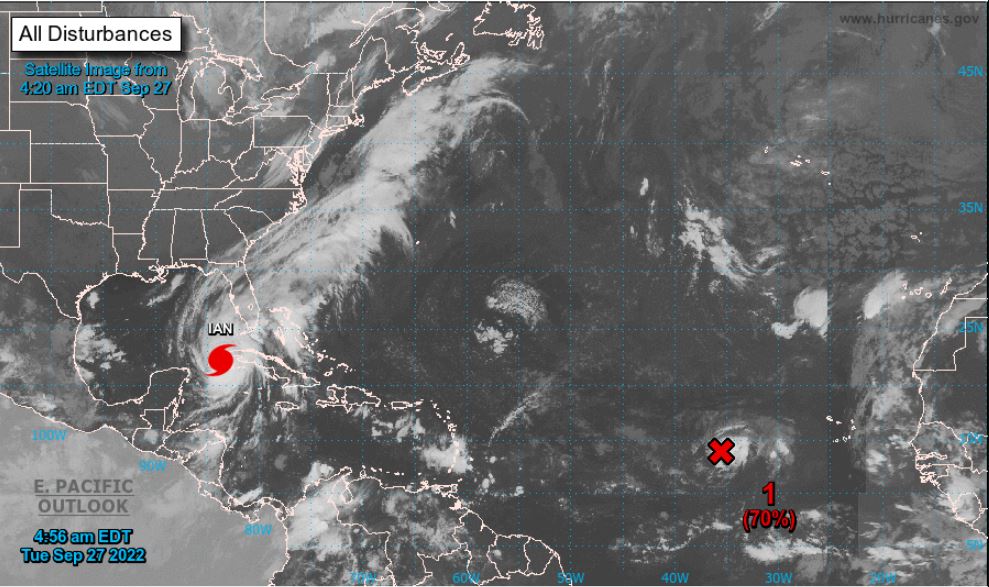

I was out cruising on the Shadow ACE the other day and decided to detour through the solar farm district. I had suspected that Next Era would be building some more solar production on one road and, sure enough, they were. A few hundred more acres were having mounting posts pounded in and panels will […]